home consulting products & tools clients about

(781)

454-7648

PCB2STL

- 3D Printed Circuit Boards

Printed circuit board (pcb) fabrication software generates a

standard format output - Gerber files (also called photoplot

files). These are used by pcb manufacturers industry wide.

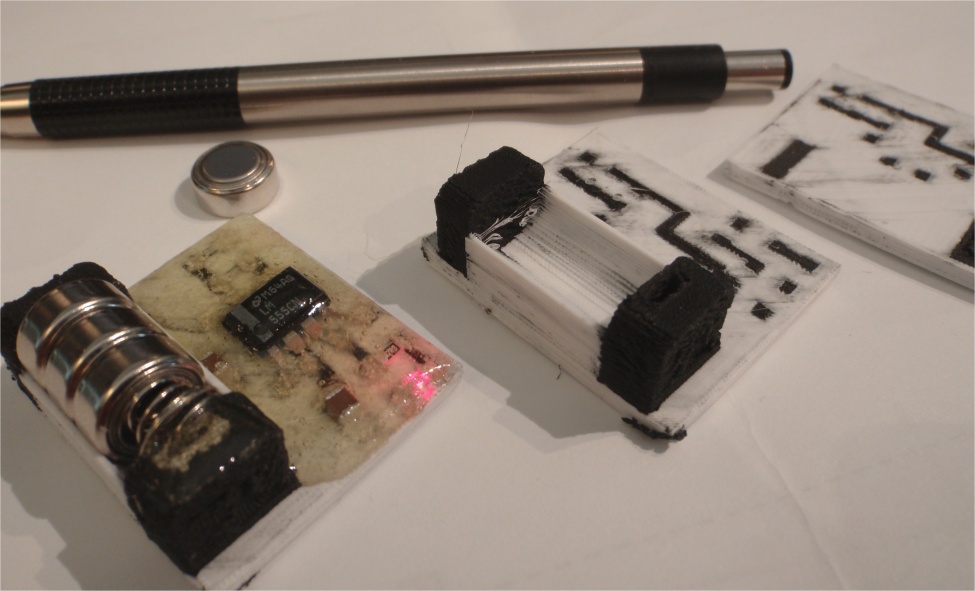

Graphene 3D Labs has perfected a highly conductive plastic fiber suitable for 3D printing. Now, with a dual head 3D printer, you can 3D print circuit boards right from the output of standard pcb layout software. PCB2STL is a tool that links the two manufacturing processes for you.

Your pcb layout software should produce a gerber file for each layer -- these include each conductor layer as well as other fabrication details such as solder mask and silkscreen images. PCB2STL will convert a gerber file for the image of one conductor layer into two STL files readable by 3D slicer software.

Thanks to Graphene 3D Labs, this software is free for you to use!

Graphene 3D Labs has perfected a highly conductive plastic fiber suitable for 3D printing. Now, with a dual head 3D printer, you can 3D print circuit boards right from the output of standard pcb layout software. PCB2STL is a tool that links the two manufacturing processes for you.

Your pcb layout software should produce a gerber file for each layer -- these include each conductor layer as well as other fabrication details such as solder mask and silkscreen images. PCB2STL will convert a gerber file for the image of one conductor layer into two STL files readable by 3D slicer software.

Thanks to Graphene 3D Labs, this software is free for you to use!

______________________________________________________________________________________________